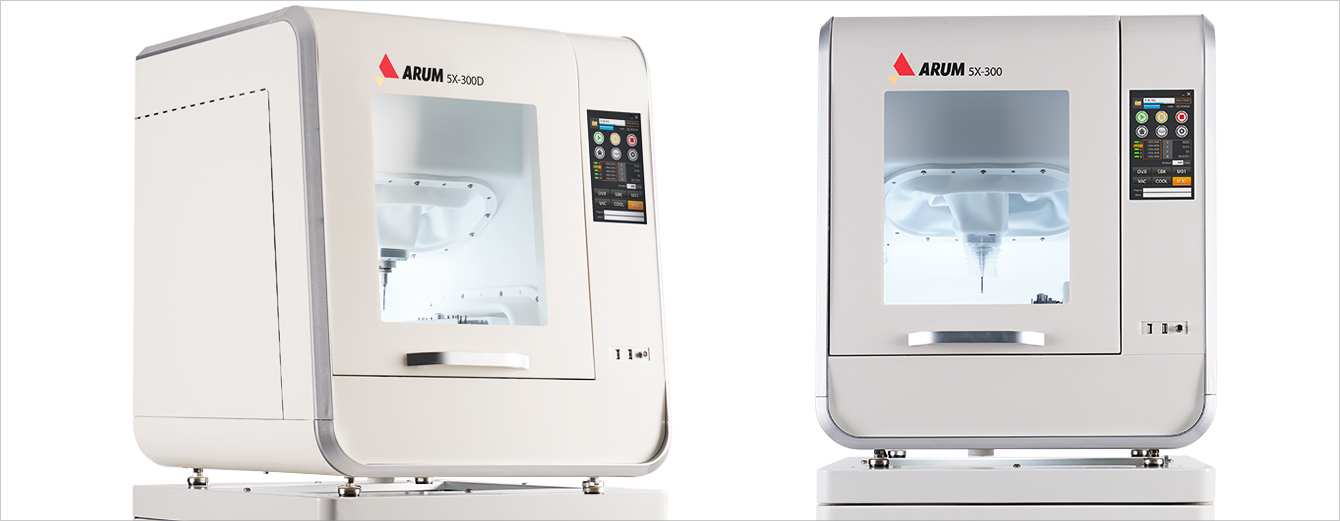

Looks Like Compact

But Not Compact

5X-300D

60,000

Dry

Dry

5Axis

5Axis

Zirconia

Zirconia

PMMA

PMMA

Amazing grinding capability

We improved user convenience by applying the cartridge that can mount and machine up to 6 CAD Blocks (Nanocomposite),

and the high-precision ball screws allows you to get high-quality milling outputs.

Like natural teeth

Every patient wants a prosthesis that looks natural. With milling the grooved part precisely using ARUM's 0.3mm tool for Zirconia, you can reproduce the teeth that look natural.

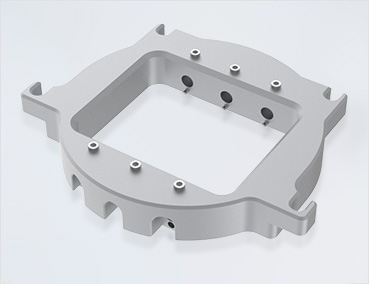

Dedicated template for ARUM,

Outcome of our extensive know-how

Based on our extensive know-how accumulated over many years and

various machining bases around the world, we provide the optimal

dedicated template for ARUM for any cases such as CAD Block,

and Zirconia Disk, etc.

This is ARUM’s unique asset that that cannot be provided anywhere else.

Free shape machining

5 axes (with A-axis rotating ±30˚ and B-axis rotating 360˚) allow you to machine freely. You can machine almost every shape from soft materials, such as Crown & Coping Bridge, Hybrid Abutment, Model, and Bite Splint, etc. and CAD block.

Device to automatically

exchange 12 tools

With a 12-tool pocket, you can machine almost every material such

as Zirconia, PMMA, PEEK, and WAX in just one setting,

and the automatic tool change function allow you to use equipment without

interruption.

The beginning of a small change

With a small change of ‘7° Tilted Door’ to ensure user's viewing angle, you can clearly see the milling progress. With the door opening wide, you can secure enough work space to conveniently change materials and setting tools. In addition, the interior floor is inclined for convenient cleaning.

User-friendly use environment

With Auto Calibration Function, you can maintain

the best condition of machine anytime, anywhere.

You can always see a certain level of machining.

U.I design with enhanced ease of use makes operation

of equipment easy and simple.

Finished product

5X-300D

Materials

5X-300D

Applications

5X-300D

Specifications

| Model | 5X-300D | |

|---|---|---|

| Axis | 5-Axis | |

| Processing | Dry | |

| Spindle Power | AC 0.5kw | |

| Max. RPM | 60,000 | |

| A.T.C | 12 | |

| Tool Shank (mm) | Ø4 | |

| Motor | Stepping | |

| Drive Mechanism | Ball Screw | |

| Way System | Linear Guide | |

| Machine Size (W*D*H) | 568*638*645mm | |

| Total Size (W*D*H) | 568*641*1583mm | |

| Weight (Machine / Table) | 90kg / - | |

| Travel | X,Y,Z axis | 167*119.8*94mm |

| A axis / B axis | ±30˚ / 360˚ | |

Accessories

| Material | Code | Ø | Size | Material | Code | Ø | Size |

|---|---|---|---|---|---|---|---|

| Zirconia | ZB-46 | 2 | D2.0*L18*50 | Glass ceramic | DG-52 | 2.5 | D2.5*L13*44.5 |

| Zirconia | ZB-47 | 1 | D1.0*L16*50 | Glass ceramic | DG-53 | 1.5 | D1.5*L10*44.5 |

| Zirconia | ZB-48 | 0.6 | D0.6*L10*45 | Glass ceramic | DG-54 | 1 | D1.0*L10*44.5 |

| Zirconia | ZB-65 | 0.3 | D0.3*L12*45 | Glass ceramic | DG-55 | 0.6 | D0.6*L08*41 |

| PMMA | MOB-56 | 3 | D3.0*L20*50 | Flat endmill | ZF-70 | 1.7 | D1.7*L18*50/td> |

| PMMA | PB-49 | 2 | D2.0*L18*50 | Flat endmill | ZF-75 | 0.6 | D0.6*L08*45 |

| PMMA | PB-50 | 1.5 | D1.5*L14*47 | T-Cutter | TC-80 | 1.8 | D1.8*L08*45 |

| PMMA | PB-51 | 1 | D1.0*L10*44 | T-Cutter | TC-98 | 2 | D2.0*L08*45 |