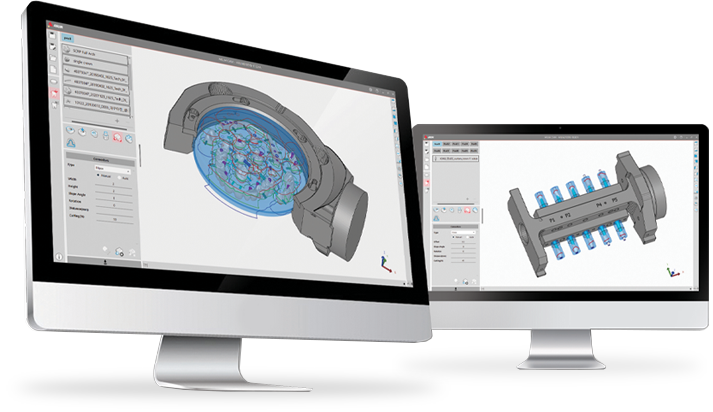

- The Perfect CAM Software

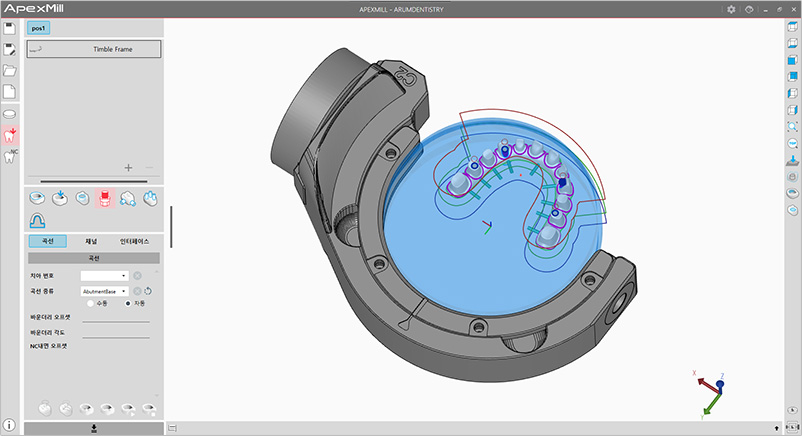

- ApexMill, developed by ARUM DENTISTRY, actively incorporates user feedback through quicker response and version upgrades. The functions of ApexMill are optimized for compatibility with milling machines from various manufacturers.

- With ApexMill, Digital Technicians can now experience a faster, easier, and more precise workflow.

The Perfect CAM, ApexMill

ApexMill is software in which all the machining know-hows of ARUM DENTISTRY are integrated. It is, above all, optimized for ARUM Milling Machine, and guarantees excellent machining quality. It provides a UI/UX environment that is easy for everyone to understand and all the core functions necessary for dental part machining. Now you can experience the most practical and most powerful CAM Design developed by ARUM DENTISTRY.

- The Fast Feedback

- We respond promptly and efficiently to user feedback.

- The Accurate Library

-

We offer an easy-to-use UI/UX environment, making it simple

for anyone to use.

- The Easy to Use

- Users can customize UI according to the equipment they handle.

- The Free OEM Customizing

- Users can customize UI according to the equipment they handle.

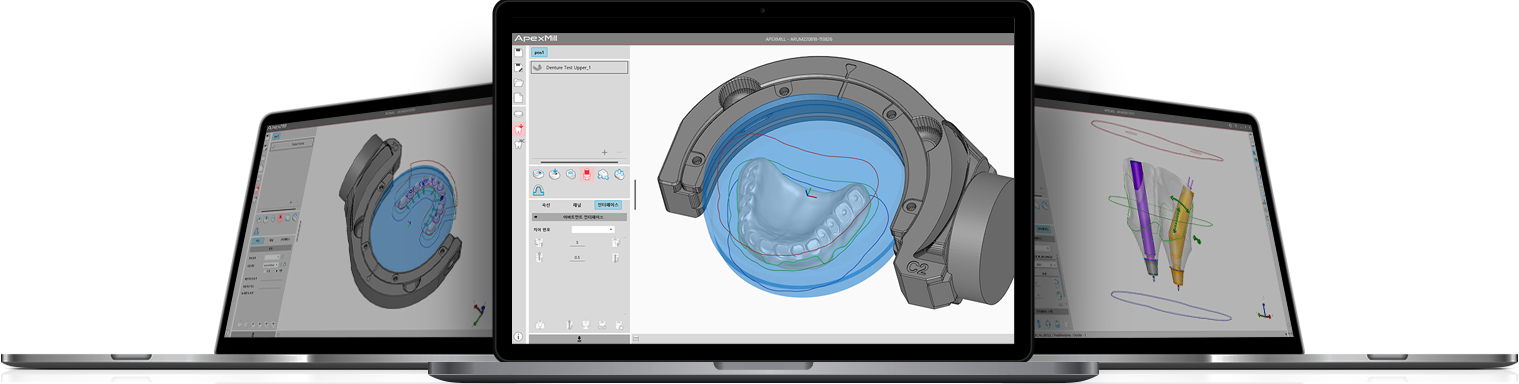

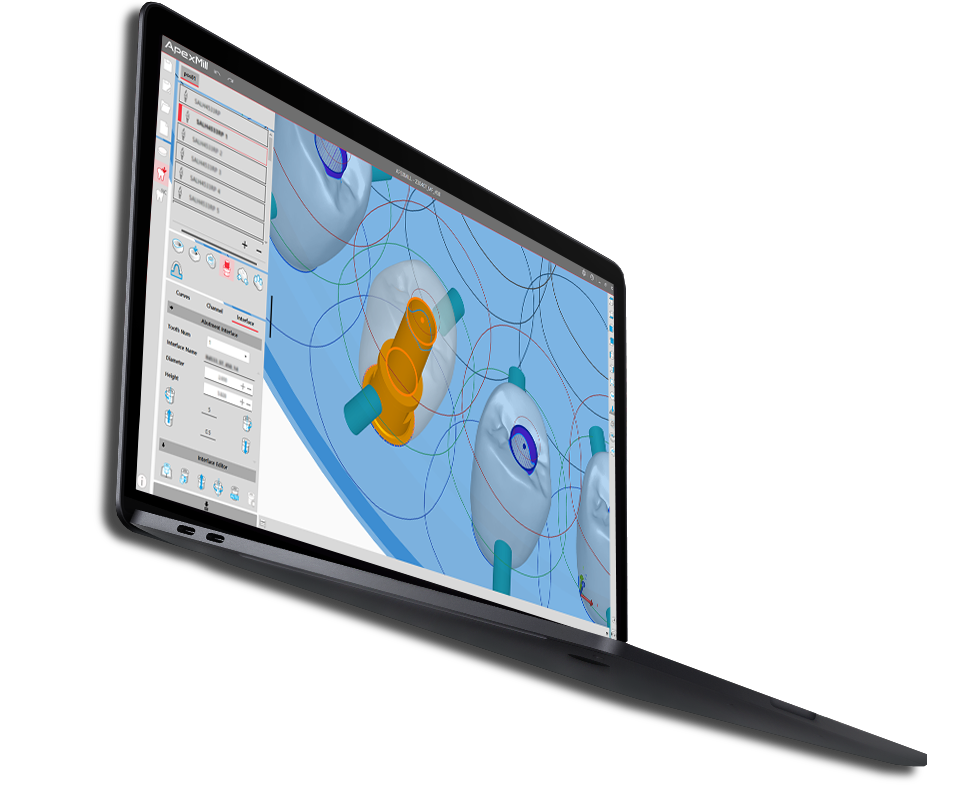

The Faster, The most powerful

CAM software

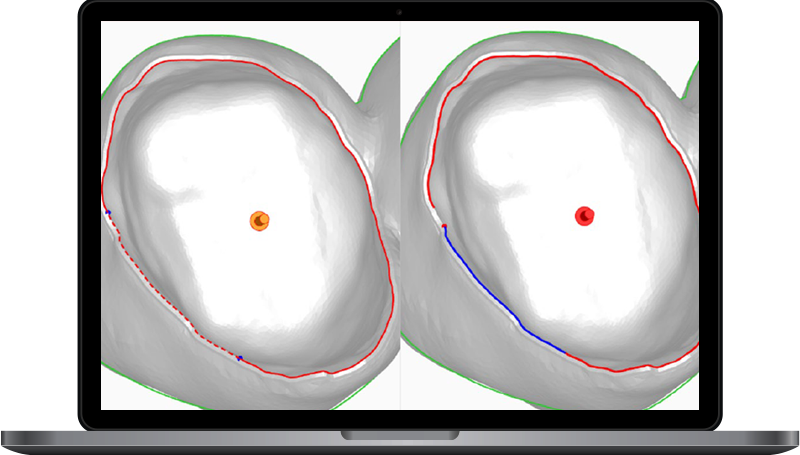

- Curve correction / Convenient margin line editing

- Users can easily correct the created curves and edit pointswith just a double-click. They can also delete a section of the curve and recreate it if necessary.

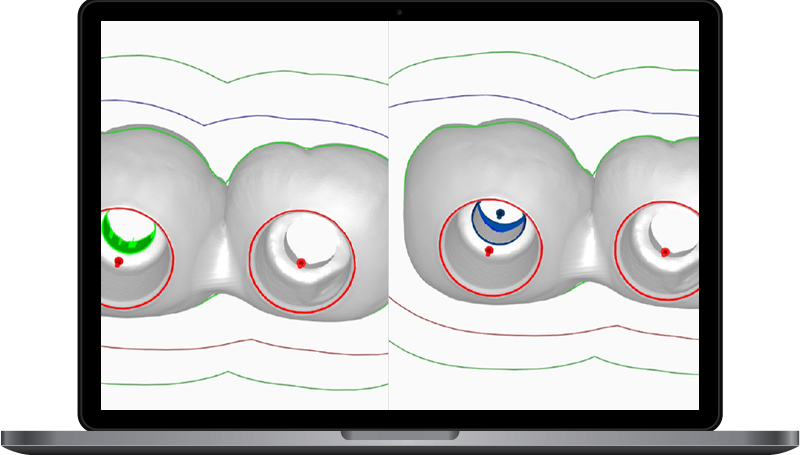

- One-Click Hole recognition / Manual Editing

- The software automatically recognizes the standard hole design through shape analysis. In case of a hole with an uneven surface, it creates the hole with just three clicks, and manual adjustments can be made for the hole's diameter, direction, and length.

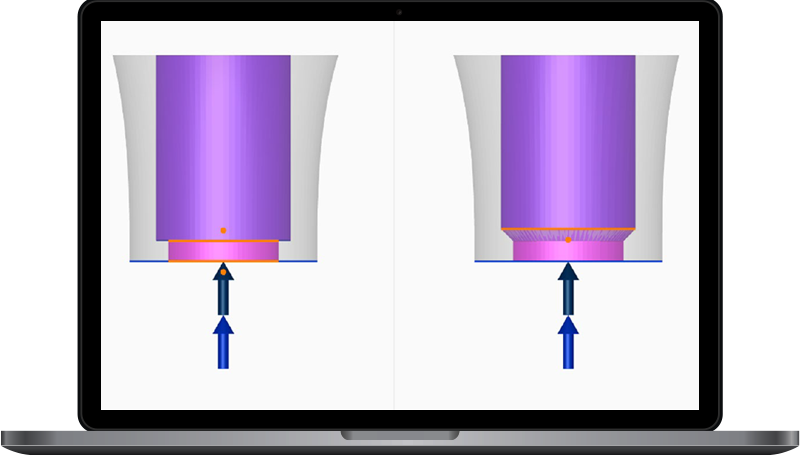

- One-Click Screw channel creation / Classification

- With a automatic One-click, the software creates a screw channel and classifies the shape of the screw seating area into either End or Taper, allowing for processing with the appropriate tool for the specific shape. (End=Flat Tool, Taper=Bullnose Tool)

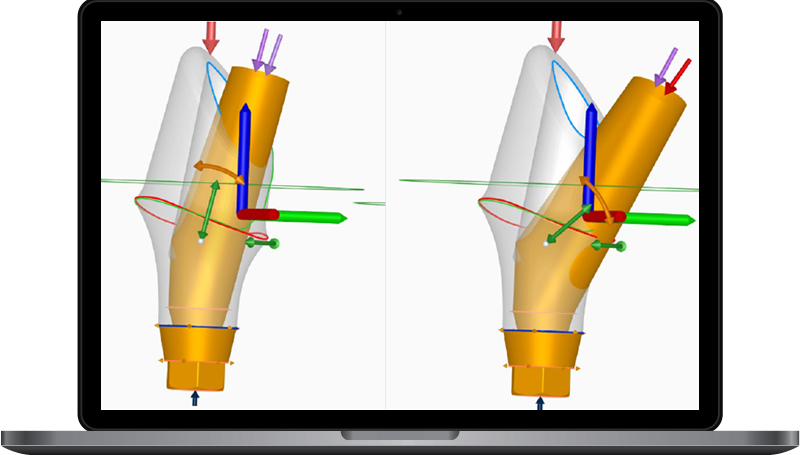

- Angled screw channel interface processing

- It enables straight or angled interface processing. For straight interface processing, users can customize the size by adjusting the diameter and height of the channel. Meanwhile, for angled interface processing, users can adjust the tilt angle and rotation direction to achieve the desired direction.

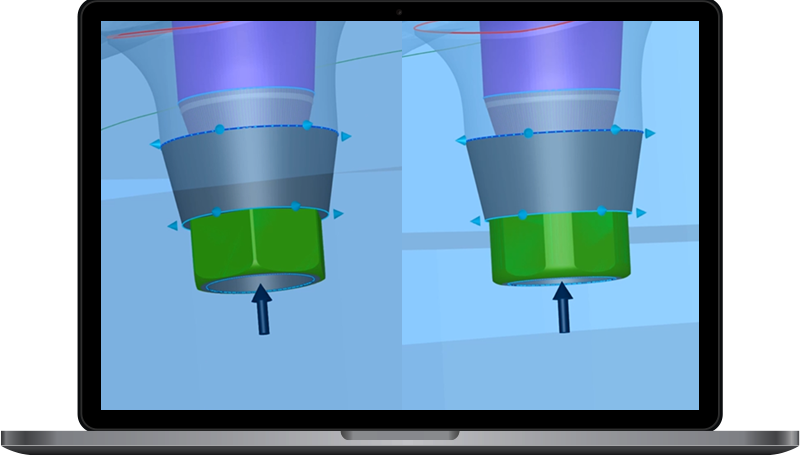

- Interface offset change

- This feature also allows users to change the size of Hexa and Top screw channel. After processing, users can assess the interface fit and make any necessary adjustments to the size, process, and save to meet their standards. All stored interface data will be automatically applied when using the program in the future.

- The Complete CAM, ApexMill

-

Required for processing

ApexMill 's function

| Function | Description | |

|---|---|---|

| Set-up | Check Project Open Part | For the part added to the project, users can review and make adjustments at any point, even after altering or removing the path. |

| Designate Dry/Wet when creating a project | Users can choose between Dry or Wet type when creating a project, or switch between the two before creating an NC file. | |

| Real-time change scale factor | Users can adjust real-time the scale factor if no parts in the project are locked. | |

| Select Milling template by default | It is a convenient feature that enables users to use their preferred Milling template continuously by specifying a default value. | |

| Set screen theme(Light & Dark) | Users can choose from light mode, dark mode, or custom mode themes for the screen. | |

| Setting | Automatically minimize undercut | Users can automatically adjust the margin in the insertion direction to minimize undercut by adjusting the inner direction to the minimum. |

| Provide various sinter frames | Users can create different sinter frames and automatically set the connector cut between the part and the sinter frame to 0%. | |

| Correct fixture position values | Users can effortlessly adjust the coordinates of Premill in the settings window. | |

| Automatically attach interface | Users can automatically attach the interface created in the information file when adding a part. If the interface is not automatically attached, users can attach it manually using a group button that is not in the information file. | |

| Display custom area names | Users can display texts relevant to the situation when setting a custom area number. | |

| Display warnings when creating connector | Users can be alerted with a red warning when a connector is created at the margin curve location. | |

| Processing | Rough processing for drill | During rough grinding, users can maximize the use of the drill tool length by leaving a pillar for drilling holes and creating screw channels while processing. |

| Process using exclusive denture tools | Users can reduce the time in rough grinding by using a 4.5mm tool and optimize undercutting using a lollipop tool. | |

| Printing | Save the simulation list | Users can save a list of simulations for which NC creation has been completed. |

| Convenience functions | Users can divide and print NC files into multiple parts using a single strategy. Users can configure a warning pop-up display to appear when the direction exceeds the direction exceeds the machine limit. In the created NC file, users can print our NC again after selecting the desired process. | |

| Line-up | Premium 5X | ASC Edition | Basic 5X | Basic 4X | |

|---|---|---|---|---|---|

| Function | Axis | 5 Axis | 5 Axis | 5 Axis | 4 Axis |

| Nesting | ● | ● | ● | ● | |

| Simulation | ● | ● | ● | ● | |

| ASC | ● | ● | ● | - | |

| Interface Library | ● | ● | - | - | |

| Multi Start | ● | - | - | - | |

| Support | Crown & Coping | ● | - | ● | ● |

| Inlay, Onlay | ● | - | ● | ● | |

| SCRP Crown, Hybrid | ● | - | ● | ● | |

| Abutment | ● | ● | ● | ● | |

| Bar bridge | ● | ● | ● | ● | |

| Bitesplint | ● | - | ● | ● | |

| Denture | ● | - | ● | ● | |

| Partial | ● | - | ● | ● | |

| Surgical Guide | ● | - | ● | ● | |

* Nesting : This feature allows users to arrange parts by rotating, moving, tilting, etc.

* Simulation : A simulation function to preview the outcome of NC creation.

* ASC : Angled Screw Channel.

* Interface Library : A library function to attach an interface to the abutment.

* Multi Start : This is a function that enables users to run multiple programs simultaneously

| Function | Recommended Specifications | *Minimum Specifications |

|---|---|---|

| Operating System | Windows 10 x 64 | Windows 7 x 64 |

| CPU | Intel i7, i9 3.6GHz | Intel i7 1.3GHz |

| Graphics Card (VRAM) | Nvidia (6GB) | 128 MB |

| RAM | 32 GB | 8 GB |

| HDD | 1 TB | 250 GB |