Faithful Mill for

Main Prosthesis

5X-450

Wet

Wet

Dry

Dry

OCC

OCC

Cuff

Cuff

CAD Block

CAD Block

Labial

Labial

Zirconia

Zirconia

5X-450 for machining various

prostheses at reasonable price

With use of open C type cartridge, you can precisely machine Labial Side (Buccal Side) and Under-Cut zone that requires additional machining.

With the amazing power of the best-in-class spindle AC 1.28kw, you can machine various shapes and materials such as Denture, Zirconia, CAD Block,

and Titanium milled Bar. etc. (Except for Ni-Cr / Co-Cr Disk)

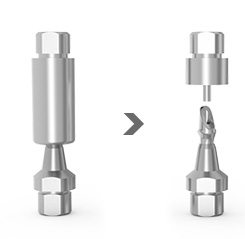

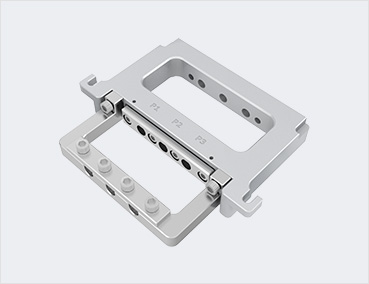

Machining with the removal

of connector

You can mount 5 Pre-milled Blanks and

machine Customized Abutment with removal of

Connector using AT Holder and Attachment.

The removal of Connector increases the degree

of bonding with the upper prosthesis and reduces

the workers’ post-stage works, improving work efficiency.

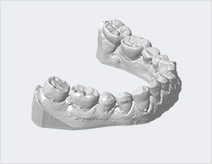

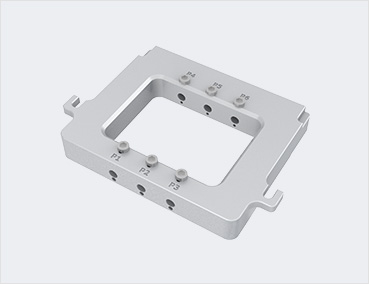

Differentiated round bar machining

You can machine Cuff Side (Gingival area), Occlusal Side, Connectorless,

and Retention Groove in simple Top & Bottom Side milling using AT cartridge.

Anyone can easily produce high quality Customized Abutment.

Dedicated template for ARUM,

Outcome of our extensive know-how

With the application of our know-how in ‘Machining the dedicated template for ARUM and Implant Connection’ accumulated through our experience of machining 5X-200 screw type prostheses to 5X-450, you can machine high quality screw-type prostheses (Bar, Screw Retained Crown & Bridge). This is ARUM's unique asset that cannot be provided anywhere else.

Maintenance of

the best use conditions

With Auto Calibration Function, users can maintain

the best condition of machine anytime.

In particular, with Auto Calibration function

by the location of Pre-milled Blank,

you can produce high accuracy Customized Abutment.

Finished product

Materials

Applications

(Crown & Coping)

Specifications

| Axis | 5-Axis | |

|---|---|---|

| Processing | Wet and Dry | |

| Spindle Power | AC 1.28kw | |

| Max. RPM | 60,000 | |

| A.T.C | 15 | |

| Tool Shank (mm) | Ø6 | |

| Motor | Stepping | |

| Drive Mechanism | Ball Screw | |

| Way System | Linear Guide | |

| Machine Size (W*D*H) | 791*791*790mm | |

| Total Size (W*D*H) | 791*791*1657mm | |

| Weight (Machine / Table) | 185kg / 65kg | |

| Travel | X,Y,Z axis | 245*116*130mm |

| A axis / B axis | 360˚/ ±35.1˚ | |

Accessories

| Material | Code | Ø | Size | Material | Code | Ø | Size |

|---|---|---|---|---|---|---|---|

| Zirconia | ZB-05 | 2 | D2.0*L20*55 | Glass ceramic | DG-21 | 1 | D1.0*L10*50 |

| Zirconia | ZB-06 | 1 | D1.0*L14*53 | Glass ceramic | DG-22 | 0.6 | D0.6*L08*50 |

| Zirconia | ZB-07 | 0.6 | D0.6*L08*50 | Glass ceramic | DG-37 | 2.5 | D2.5*L12*50 |

| Zirconia | ZB-78 | 0.3 | D0.3*L1.5*50 | Glass ceramic | DG-38 | 1.5 | D1.5*L10*50 |

| Metal(Premilled Blank/DIsk) | MB-09 | 3 | D3.0*L12*50 | PMMA(Long) | PB-88 | 3 | D3.0*L20*55 |

| Metal(Premilled Blank/DIsk) | MB-10 | 2 | D2.0*L12*50 | PMMA(Long) | PB-89 | 2 | D2.0*L20*55 |

| Metal(Premilled Blank/DIsk) | MB-11 | 1.5 | D1.5*L10*50 | PMMA(Long) | PB-90 | 1.5 | D1.5*L18*58 |

| Metal(Premilled Blank/DIsk) | MB-12 | 1 | D1.0*L10*50 | PMMA(Long) | PB-91 | 1 | D1.0*L13*55 |

| Metal(DIsk) | MB-14 | 0.6 | D0.6*L03*50 | PMMA(Long) | PB-92 | 0.6 | D0.6*L10*55 |

| Metal(Reamer) | MR-01 | 3.5 | D3.5*L18*55*180˚ | PMMA(Denture) | PB-93 | 4.5 | D4.5*L25*60 |

| Metal(Reamer) | MR-02 | 2.6 | D2.6*L18*55*180˚ | PMMA(Lollipop) | PB-94 | 3 | D3.0*L15*60 |

| Metal(Reamer) | MR-05 | 2.3 | D2.3*L18*55*120˚ | T-cutter | TC-82 | 2 | D2.0*L08*50 |

| Metal(Reamer) | MR-06 | 2.3 | D2.3*L18*55*90˚ | T-cutter | TC-83 | 1.8 | D1.8*L08*50 |

| Metal(Reamer) | MR-07 | 2.3 | D2.3*L18*55*30˚ | T-cutter | TC-84 | 1.5 | D1.5*L08*50 |

| Metal(Reamer) | MR-09 | 2.4 | D2.4*L18*55*70˚ | T-cutter | TC-97 | 2.3 | D2.3*L07*50 |

| Metal(Reamer) | MR-10 | 2.6 | D2.6*L18*55*30˚ | Flat endmill | MF-15 | 2 | D2.0*L18*55 |

| Metal(Reamer) | MR-11 | 2.4 | D2.4*L18*55*140˚ | Flat endmill | MF-45 | 1.5 | D1.5*L07*50 |

| Metal(Reamer) | MR-12 | 2.6 | D2.6*L18*55*90˚ | Flat endmill | MF-71 | 0.6 | D0.6*L05*50 |

| Metal(Reamer) | MR-13 | 2.7 | D2.7*L18*55*70˚ | Bullnosemill | MFR-44 | 1.5 | D1.5*L05*R0.1*50 |

| Metal(Reamer) | MR-14 | 2.3 | D2.3*L18*55*70˚ | Bullnosemill | MFR-66 | 1.5 | D1.5*L14*R0.2*50 |

| Metal(Reamer) | MR-15 | 2.3 | D2.3*L18*55*180˚ | Bullnosemill | MFR-43 | 2 | D2.0*L18*R0.2*55 |

| Metal(Reamer) | MR-16 | 2.4 | D2.4*L18*55*90˚ | Thread | TH-69 | M2.0*P0.4 | M2.0*P0.4 |

| Metal(Drill) | MD-18 | 1.5 | D1.5*L14*50 | Thread | TH-70 | M1.4*P0.3 | M1.4*P0.3 |

| Metal(Drill) | MD-19 | 2 | D2.0*L18*55 | Thread | TH-95 | M1.8*P0.35 | M1.8*P0.35 |

| Metal(Drill) | MD-73 | 1.1 | D1.1*L05*50 | Thread | TH-99 | M1.6*P0.35 | M1.6*P0.35 |

| Zirconia(Long) | ZB-85 | 2 | D2.0*L25*60 | ||||

| Zirconia(Long) | ZB-86 | 1 | D1.0*L20*60 | ||||

| Zirconia(Long) | ZB-87 | 0.6 | D0.6*L10*60 |